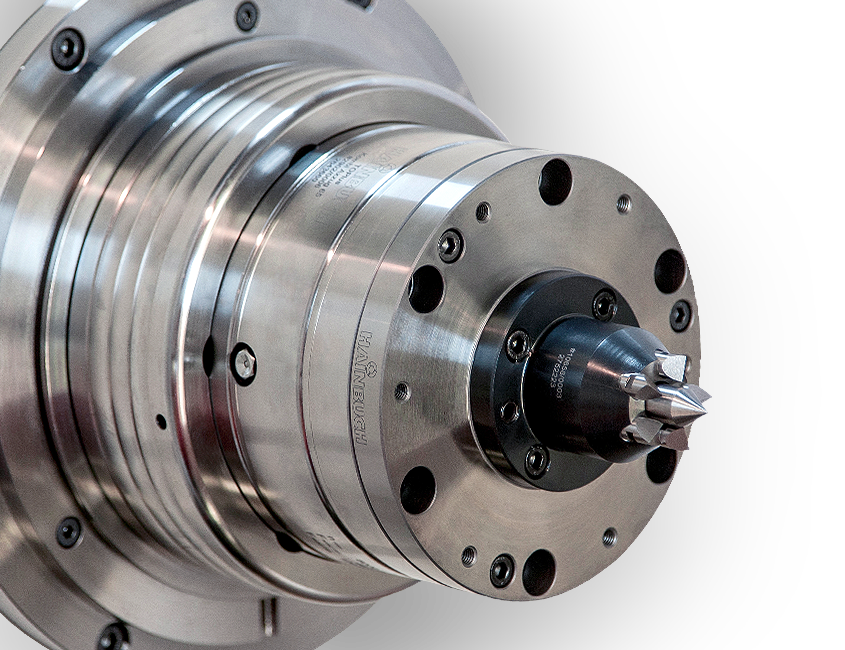

What are the benefits & application possibilities with the HAINBUCH SYSTEM?

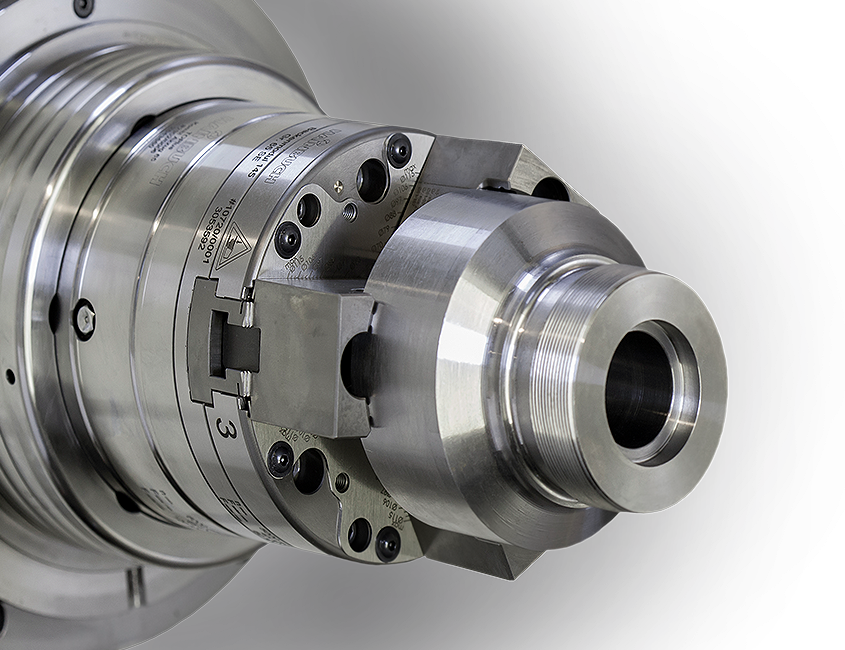

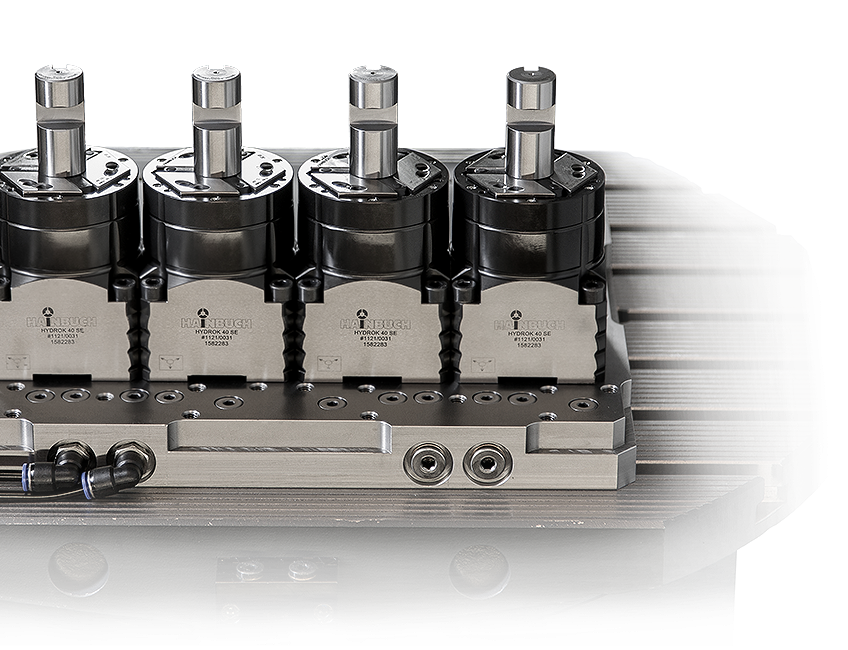

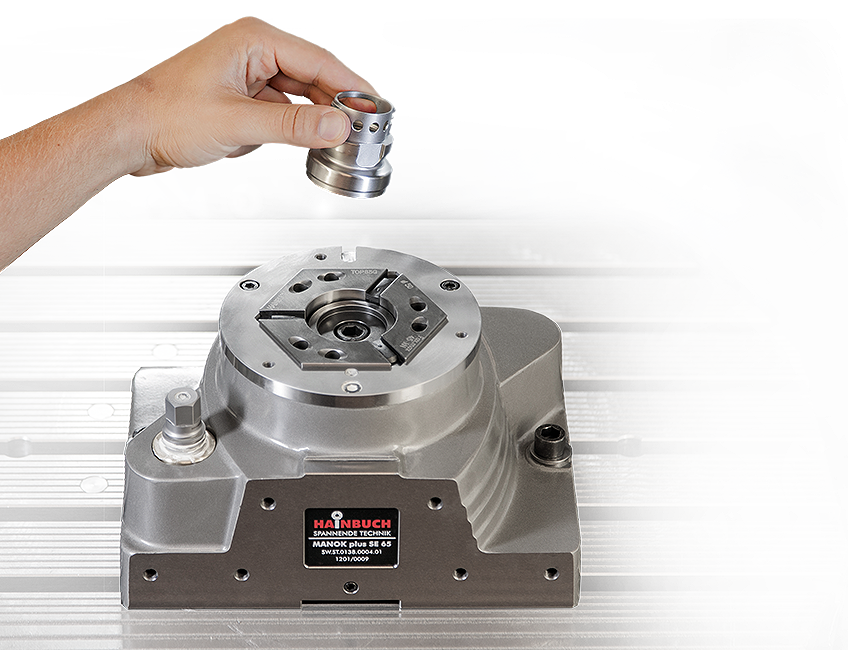

The HAINBUCH SYSTEM adapts to your workpiece. It allows you to clamp 1,000 different workpieces and gives you everything you need for complete machining.

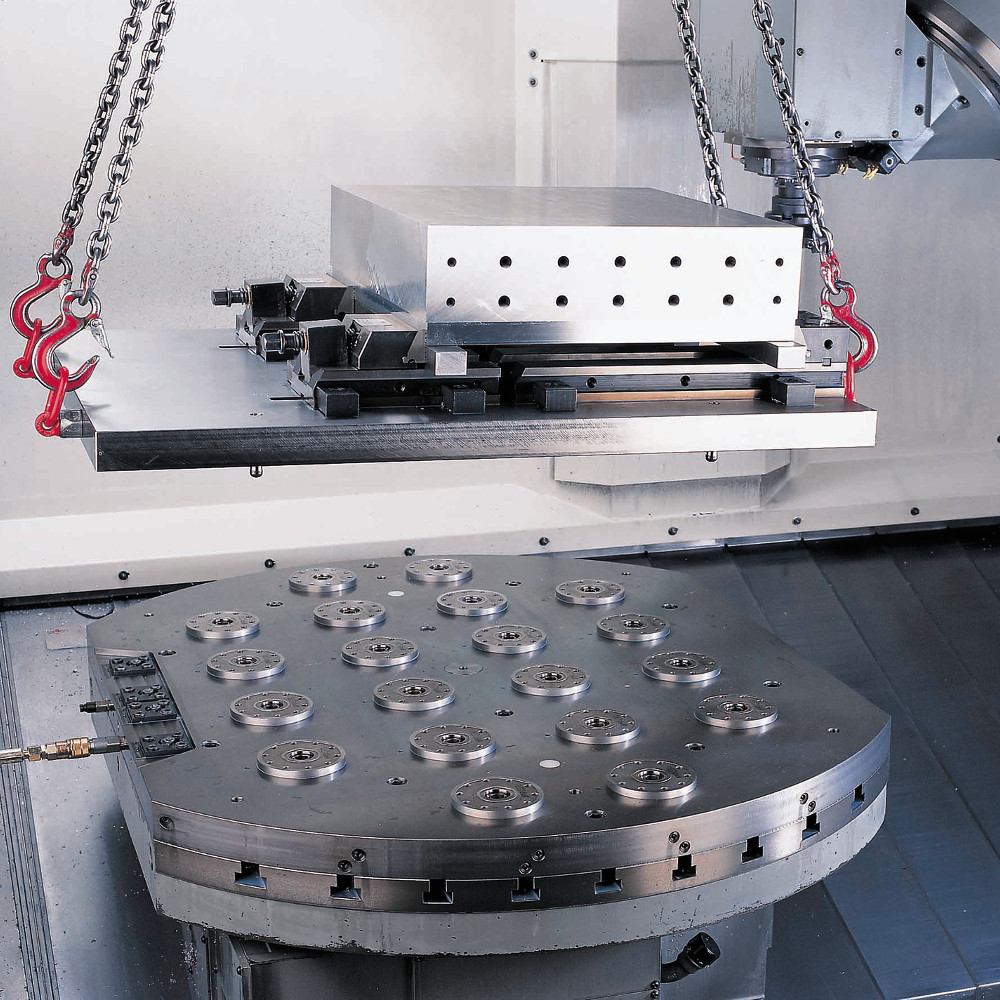

You need only one basic clamping device – a chuck or a stationary chuck that remains on the machine. For O.D., I.D., jaw or magnetic clamping, or clamping between centers you then use adaptations – without having to accept any compromises.

The workpiece defines the adaptation and converts your basic clamping device for the particular application. This incredible solution reduces set-up time substantially, while increasing flexibility and making it possible to easily squeeze in short-term jobs.

You will therefore be optimally prepared for every clamping situation – whether in turning, milling or grinding.

Application & benefits of the HAINBUCH SYSTEM

SE and RD variants in comparsion

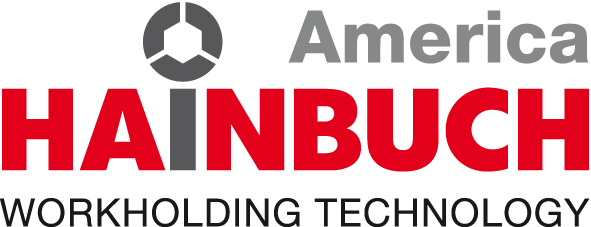

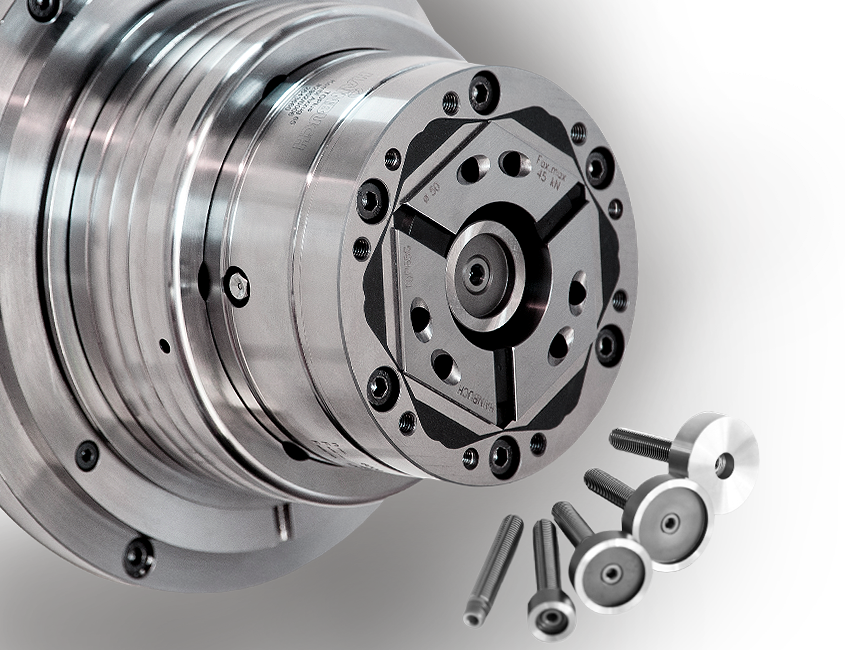

SE variant [hexagon]

The TOPlus version with hexagonal geometry offers a 25% increase in holding force, relative to the round variant and unique rigidity – thanks to full-surface contact of the clamping element in the clamping device body.

Additional benefits over the RD variant

- Higher metal removal rates, higher output, lower piece costs

- Vibration dampening effect

- Particularly efficient for difficult machining

- Sealed against contamination from outside – low maintenance, consequently less machine downtime and increased process reliability. Particularly useful for fine-particle non-ferrous metals such as brass or even cast iron. Consequently also particularly well suited for stationary machining.

- Optimal lubrication due to lubricating grooves in the chuck body

- Full through-bore or top face run on the workpiece or front end-stop

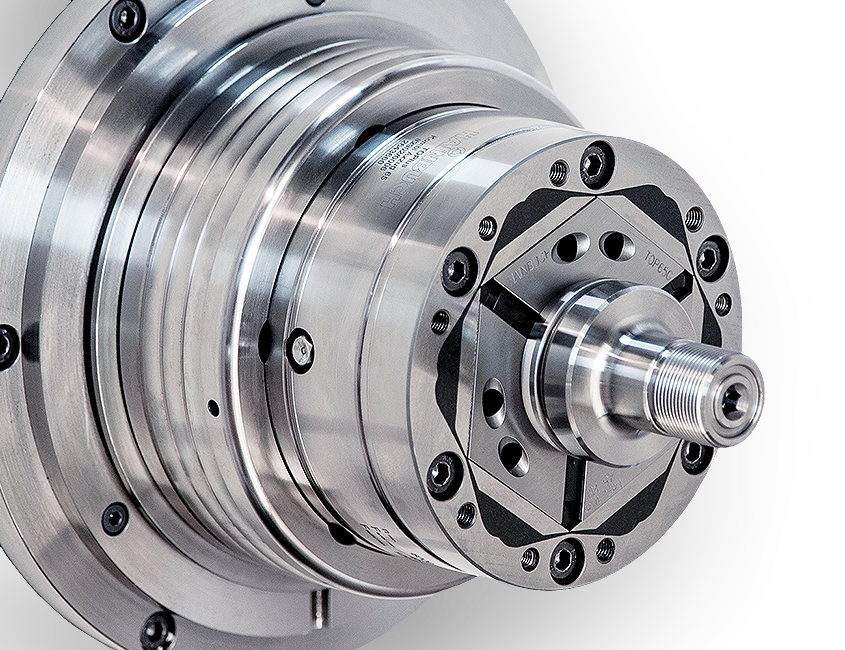

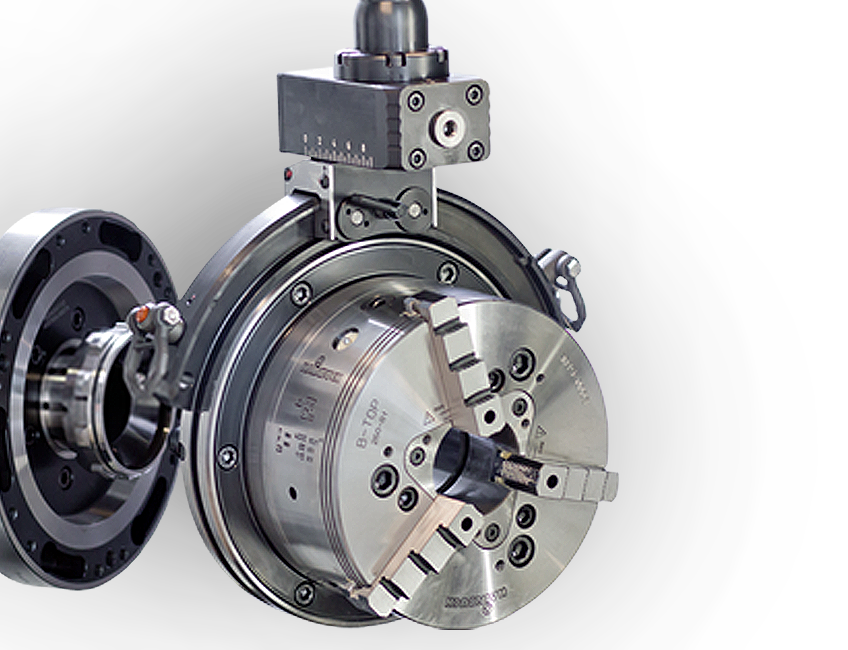

RD variant [round]

The well-known SPANNTOP version with round clamping geometry has significantly higher holding force than conventional 3-jaw chucks and collets due to the pull-back effect and circumferential clamping.

Your benefits

- High rigidity

- Precise concentricity

- Fast change-over

- Full through-bore or top face run on the workpiece or front end-stop