Workpiece

Some examples of our many clamping solutions

You also need a special solution? Our specialists are happy to help you, Phone: +49 7144.907-333.

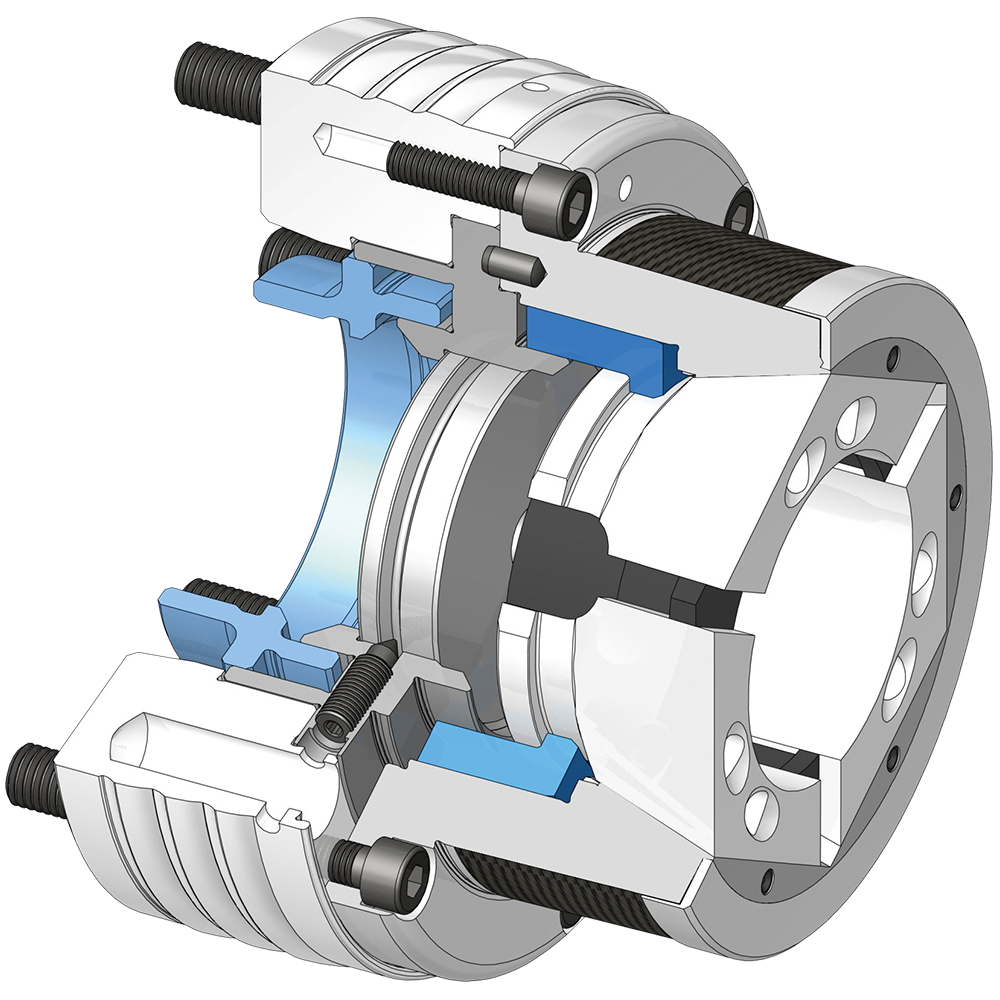

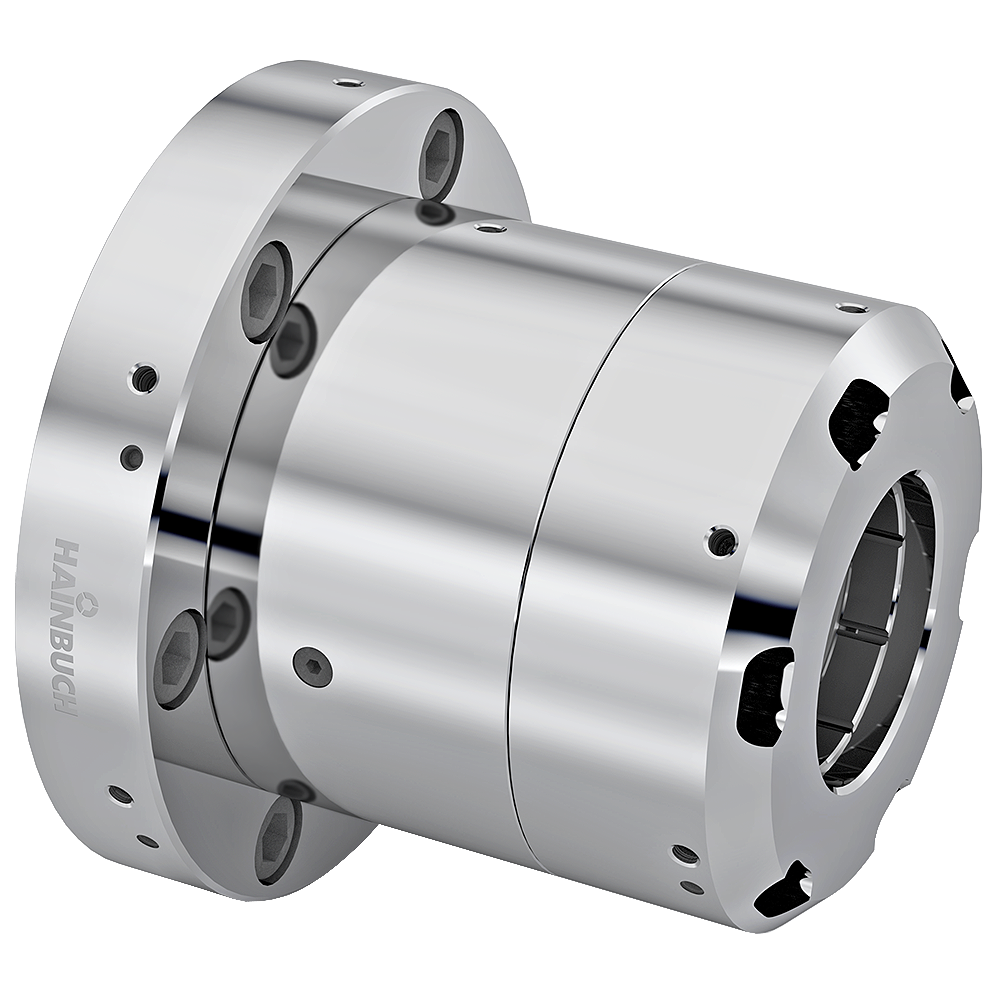

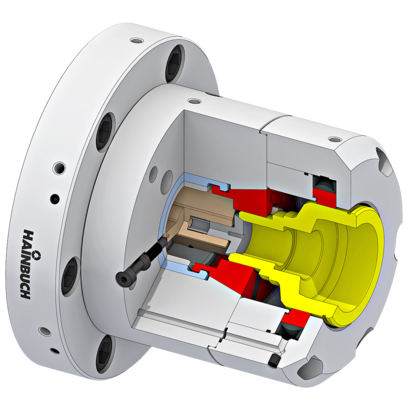

TOPlus / SPANNTOP chuck made of carbon fiber

Your benefit

- Power-operated, lightweight clamping devices for better productivity and more economical for the series production

- As much as 70 % lighter than the standard steel version, thus protecting the machine components

- Better machine dynamics due to significantly lower mass moment of inertia

- Increased productivity through faster acceleration / decelaration of the machine spindle

- Reduced energy costs

Savings

- Clamping time ist reduced by approx. 10 %

- Tool life is extended by 5 %

Results / customer benefits

- Better workpiece surfaces in every machining plane

- Higher feed rates

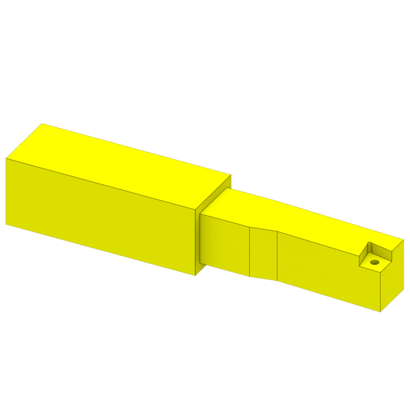

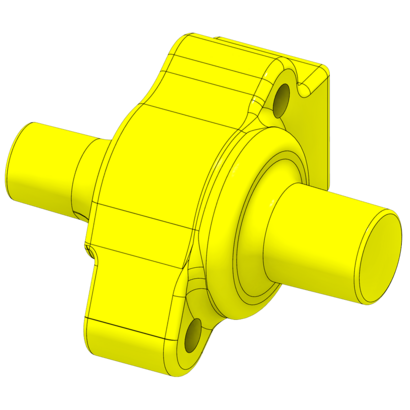

Challenge

Workpiece: Tool holder

Clamping task: 4-sided clamping from the outside

Machining: Milling of the shank and of the head

- Better workpiece surface

- More rigid clamping

Savings

- 2 clamping set-ups reduced to only one set-up

- The workpiece is produced approx. 8 % faster and though saving process time

Results / customer benefits

- Higher speeds and feed rates thanks to extremely forceful clamping

- Run-outs between centers are achieved with process reliability

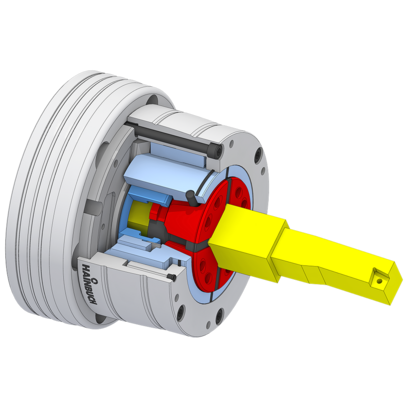

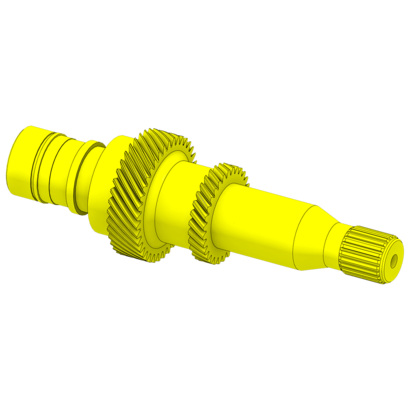

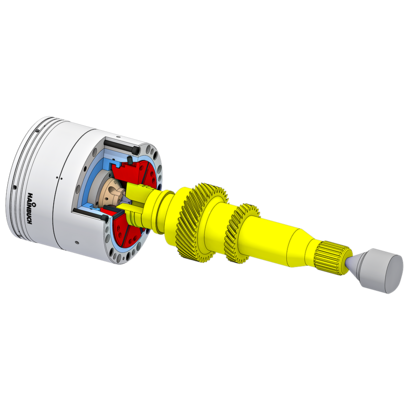

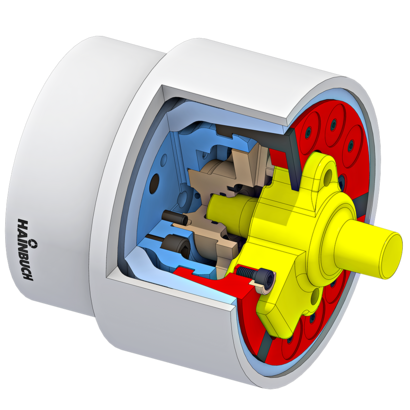

Challenge

Workpiece: Thin shaft

Clamping task: With clamping head and between centers

Machining: Roughing and finish machining in a single process

- Finishing between centers

- Highest concentricity between centers

Savings

- Elimination of the work cycle »hard turning of the bell outer Ø« | Savings: approx. 25 seconds per part

- Increased tool life from 800 to 1,200 workpieces | Savings: approx 30 % of tool costs

Results / customer benefits

- After hardening, the workpiece remains unmachined on the support surface

- One complete manufacturing process is eliminated

Challenge

Workpiece: CV joint

Clamping task: O.D. clamping

Machining: Hard machining

- Rigid support at the machining point

- Position errors of the axis of clamping relative to the support axis are compensated

- Form-compensating support

Savings

- Manufacturing with process reliability

- Scrap reduced to »0«

Results / customer benefits

- Thanks to the enclosing clamping device the workpiece remains securely in the clamped position in spite of high RPM

- Highest clamping forces

- Large radial clamping strokes

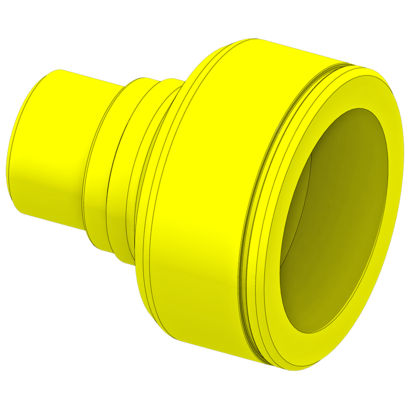

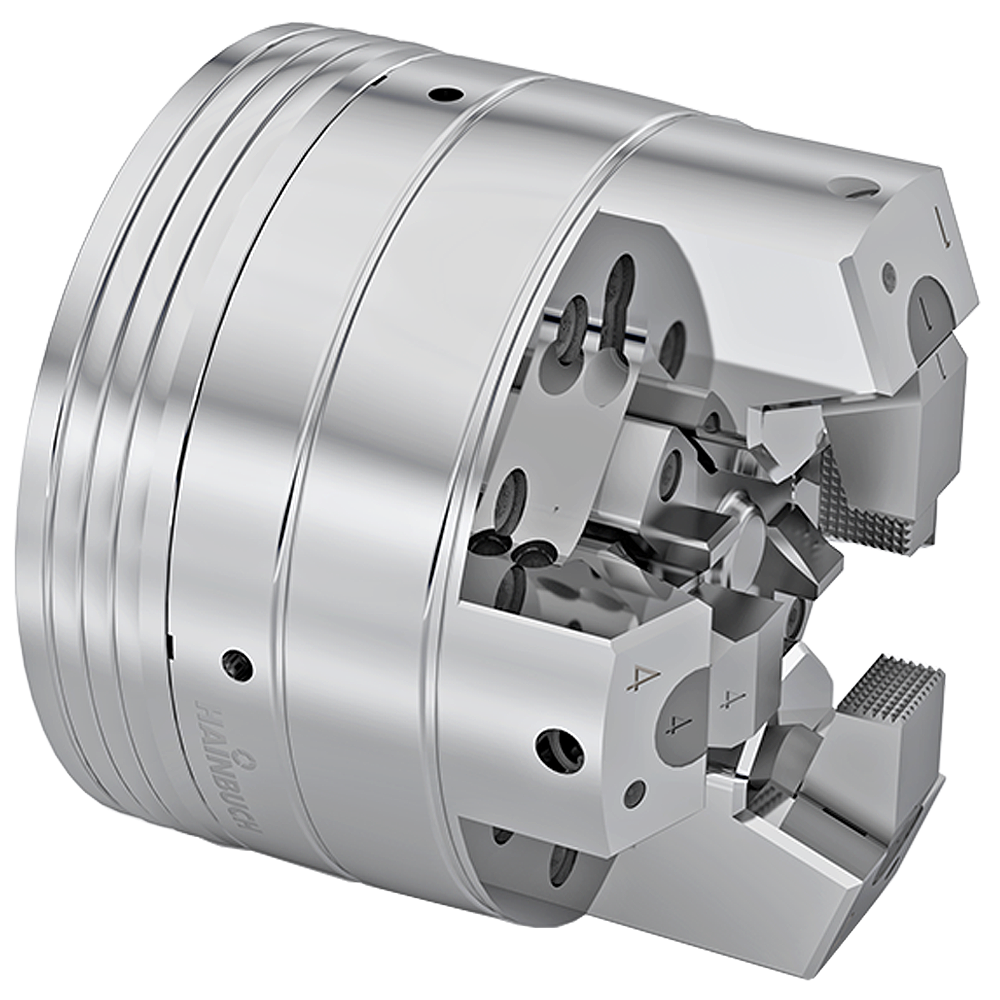

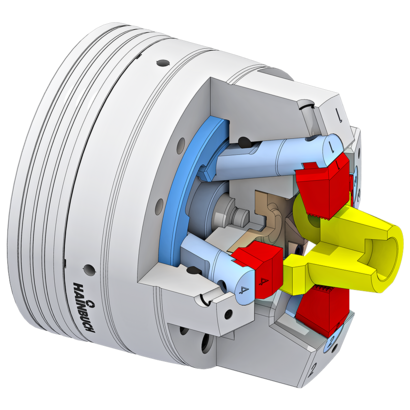

Challenge

Workpiece: Casting

Clamping task: O.D. clamping of a blank

Machining: Turning and drilling

- Centrifugally stable clamping even at high RPM

- Integrated balancing system

Savings

- The inexpensive pre-process remains the same

- Easy handling of the finished part for further processing thanks to extremely precise symmetry on the component

Results / customer benefits

- Low-maintenance clamping device

- Stable and rigid clamping

- Different profiles can be set-up easily

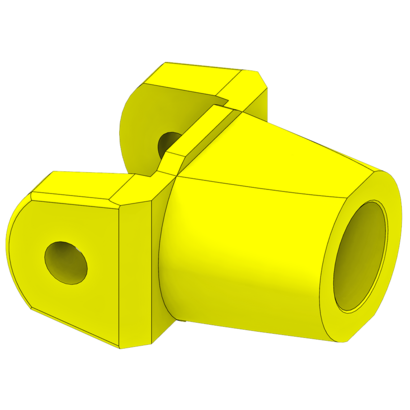

Challenge

Workpiece: Fork-head

Clamping task: O.D. clamping

Machining: Turning

- Compensation of the blank tolerances of 1.5 mm in both clamping directions

- Interrupted cut during turning