Product sheet

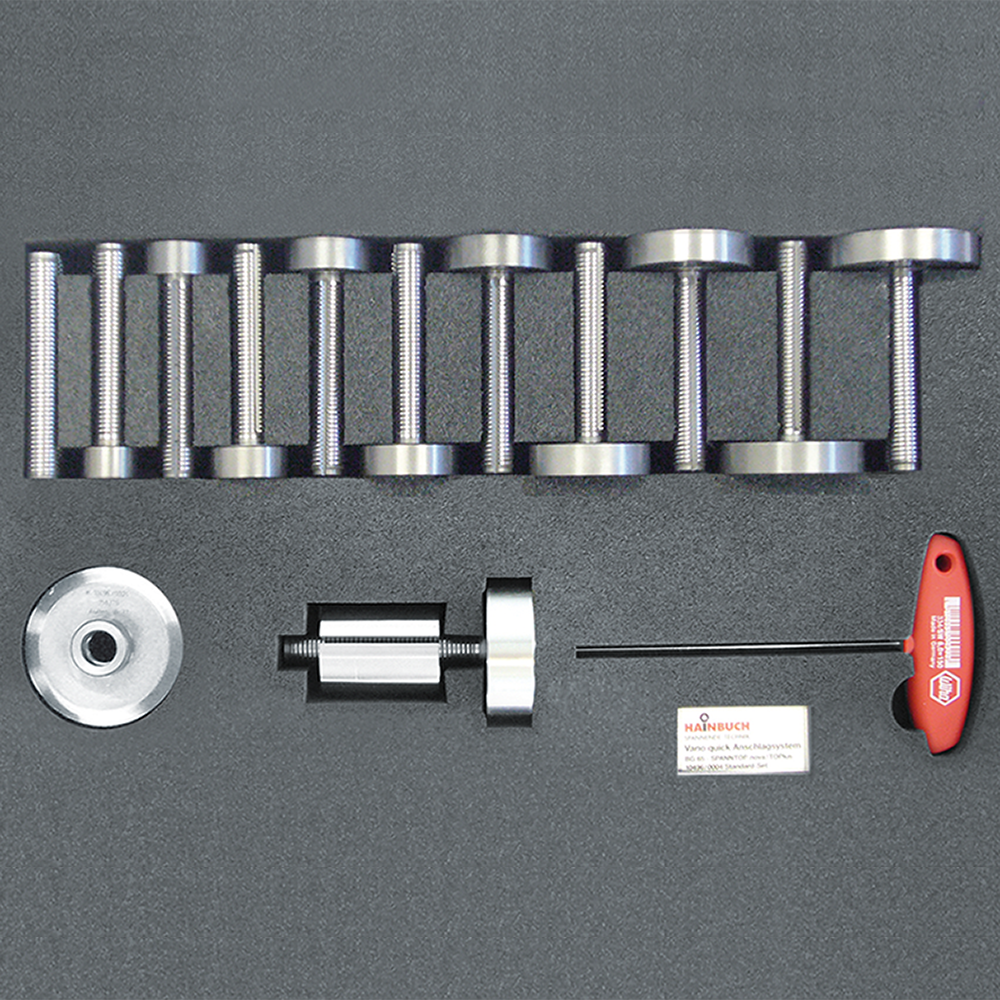

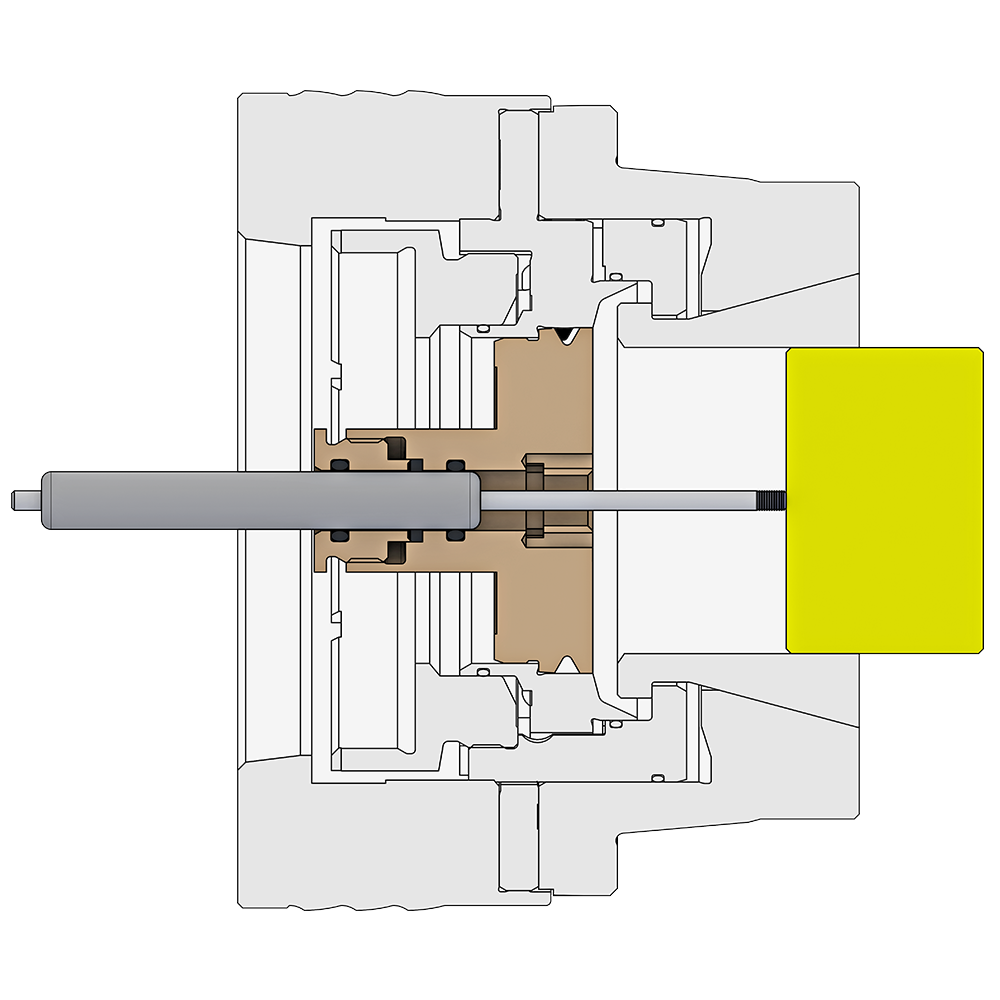

End-stop system vario quick

The vario quick is an end-stop system with standardized adjustable workpiece end-stops. It saves valuable work preparation time and gives you significantly more flexibility. Since you always have the required clamping length on hand – without having to produce the end-stops yourself.

The clamping length is set for the end-stop screws / blank screws via a threaded spindle. One half turn corresponds to 1 mm adjustment travel.

The sets can be expanded individually with separately available end-stop and blank screws. The vario quick end-stop system can also be used stationary under specific conditions [table bore required].

Advantages

- Standardized workpiece end-stops

- End-stop depth can quickly be adjusted in 1 mm increments

- End-stop blanks available

- Can be used rotating and stationary

- Practical storage box

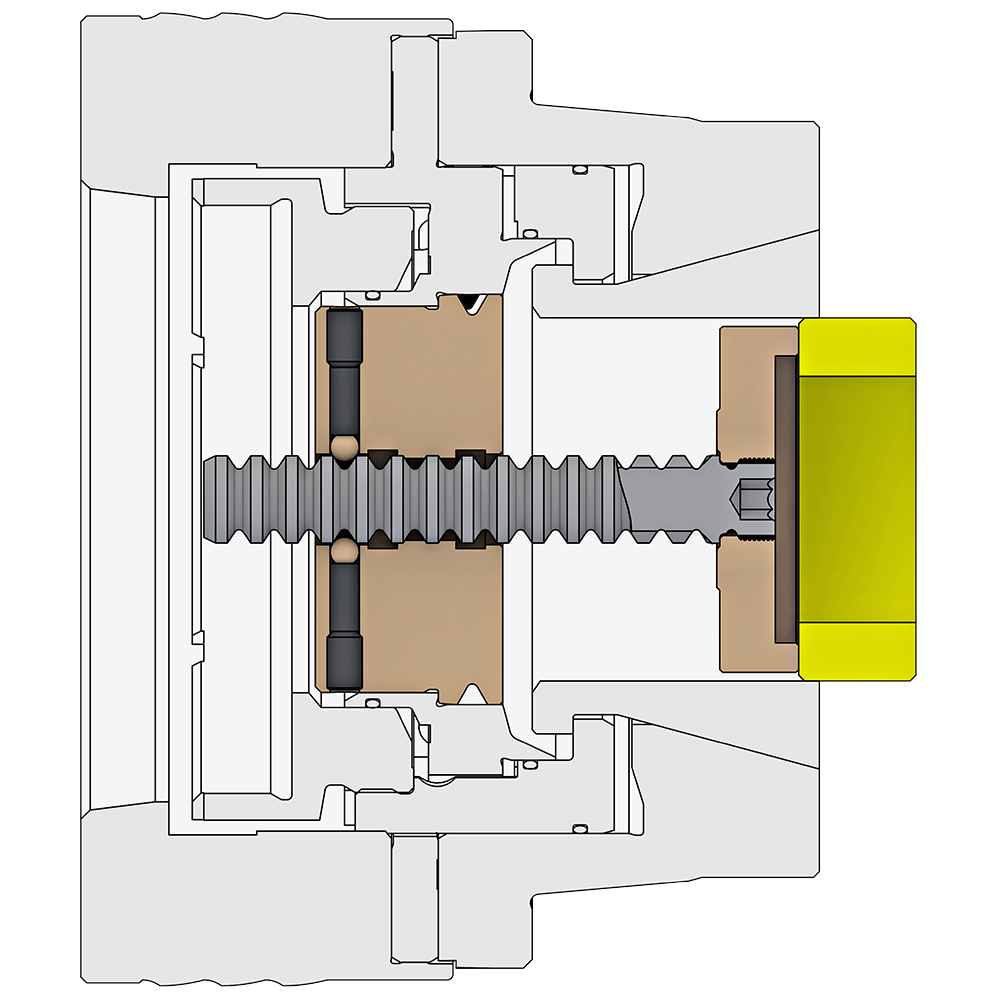

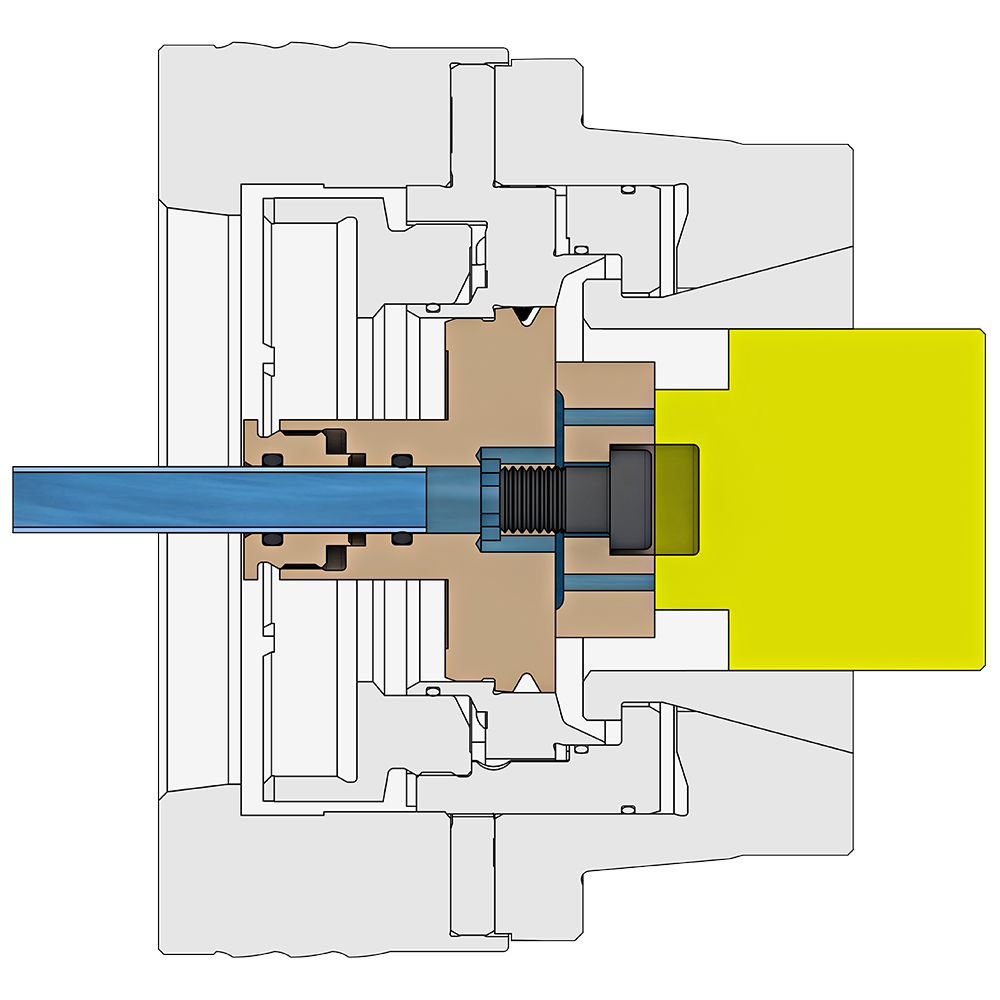

End-stop system vario flex

With the vario flex gas pr essure workpiece ejector the machined workpiece is automatically ejected out of the clamping device. This automation increases your process reliability and reduces cycle times.

Moreover, the vario flex workpiece ejector can also be used as base end-stop for the flushing or air sensing system connection. Therefore the gas pressure spring is removed and replaced with a media connection. In addition, a workpiece-specific end-stop including flushing & air system holes can optionally be foreseen and can be mounted directly on the flexible interface.

Advantages

- For automatic ejection of the workpiece out of the chuck

- Workpiece ejector or base end-stop for flushing or air sensing system