Workpiece

Some examples of our many clamping solutions

You also need a special solution? Our specialists are happy to help you, Phone: +49 7144.907-333.

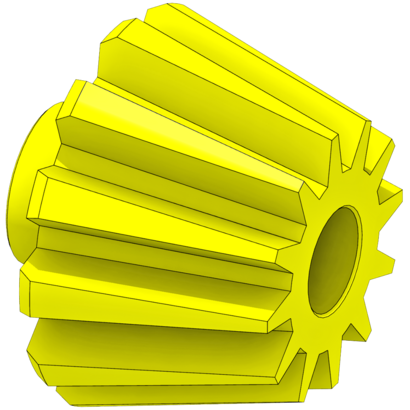

Savings

- Tool life is extended by 5 %

- Manufacturing with process reliability

Results / customer benefits

- Stable and reliable process for gear manufacturing

- Large opening stroke to ensure secure loading

Challenge

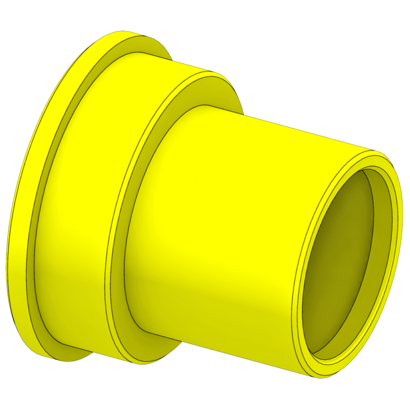

Workpiece: Bevel gear

Clamping task: I.D. clamping

Machining: Gear hobbing

- Generate the maximum clamping forces in the smallest installation space

- Maximum rigidity

- Suitable for mass production

Savings

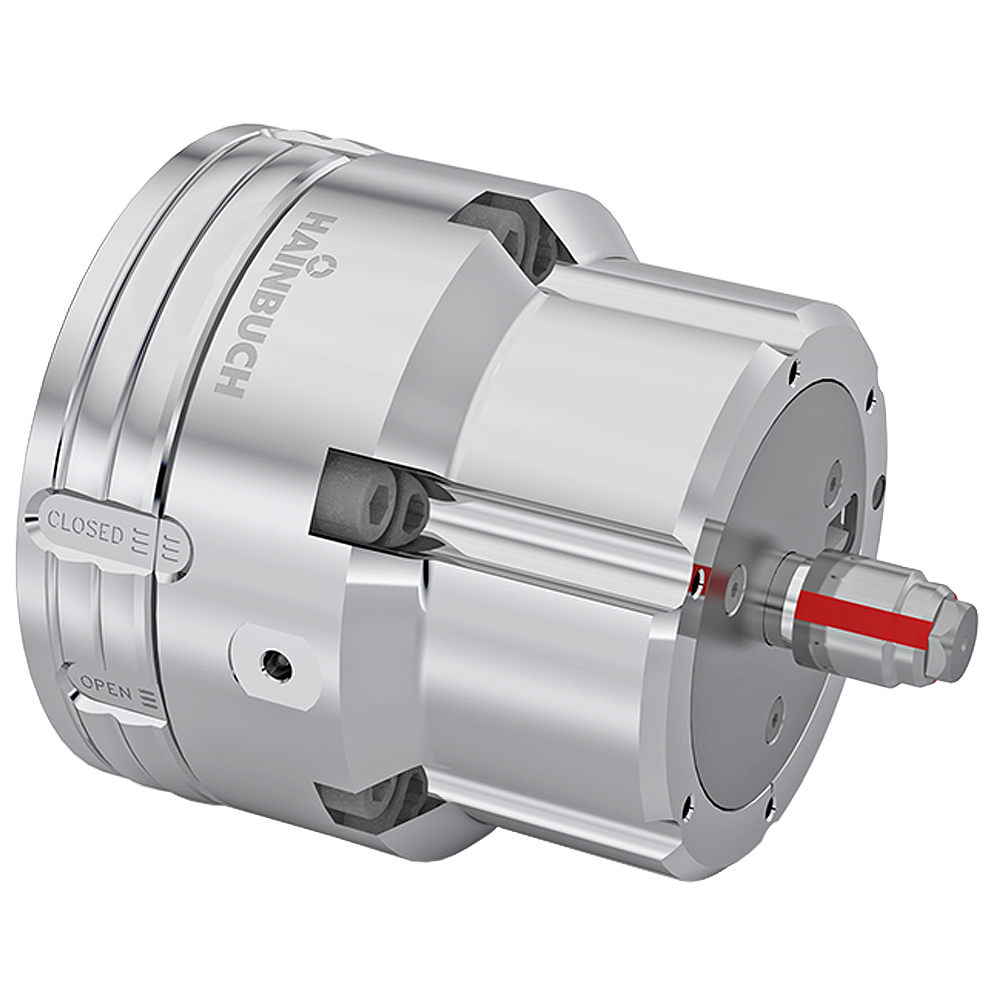

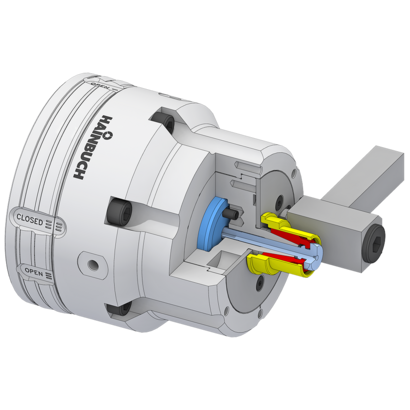

- Reduction of the annual total investment for clamping devices by approx. € 10,000.00

Results / customer benefits

- Service life of the clamping device has been significantly increased

- High-precision change interface provided for clamping device change-over

Challenge

Workpiece: Gears

Clamping task: I.D. clamping

Machining: Milling of the gear teeth

- Mass production of small gears

- Different clamping diameters must be interchangeable

- Long service life of the clamping device

Savings

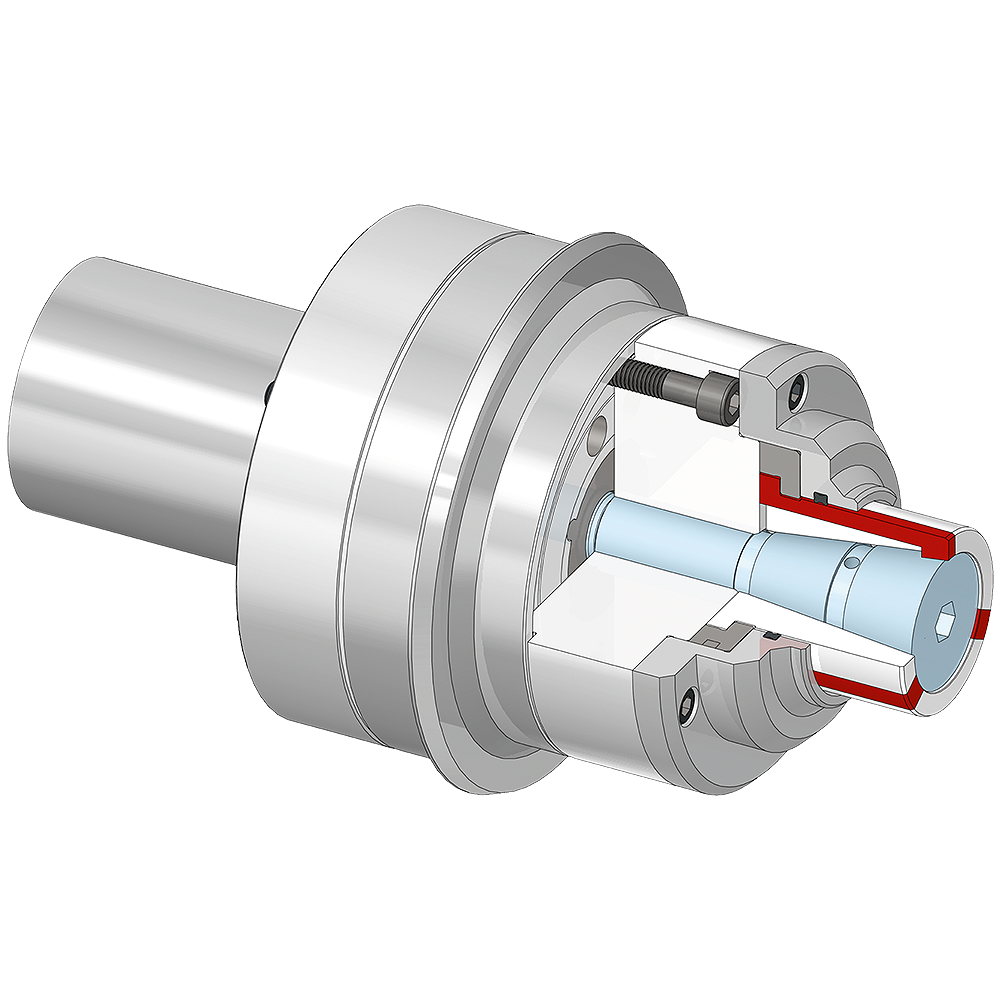

- Higher feed rates possible | Time savings: 35 %

Results / customer benefits

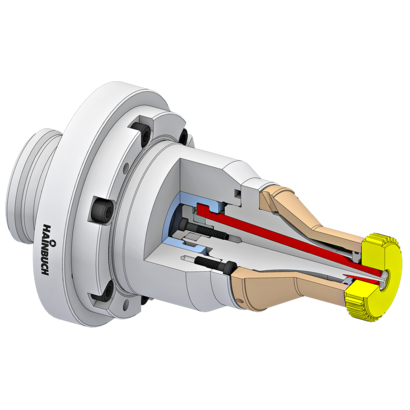

- Run-outs between centers within 3 μm

- Center must only be aligned once

Challenge

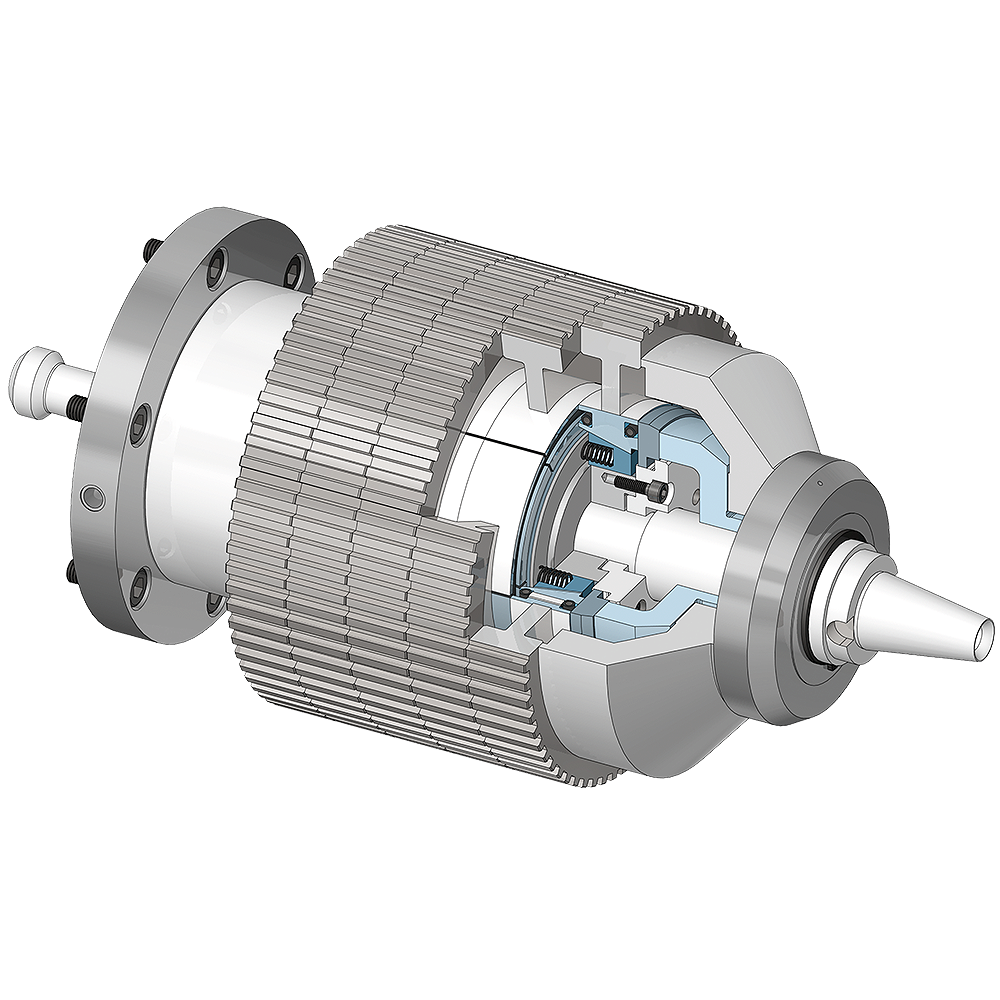

Workpiece: Tube shaft

Clamping task: Compensating I.D. clamping as torque entrainment

Machining: Grinding of the outer contour

- Inner contour as clamping reference with run-out error to the centers

- Run-outs between centers within 5 μm

- Guided rotation must be position-compensating

Savings

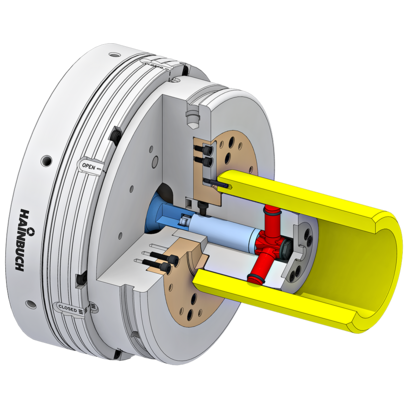

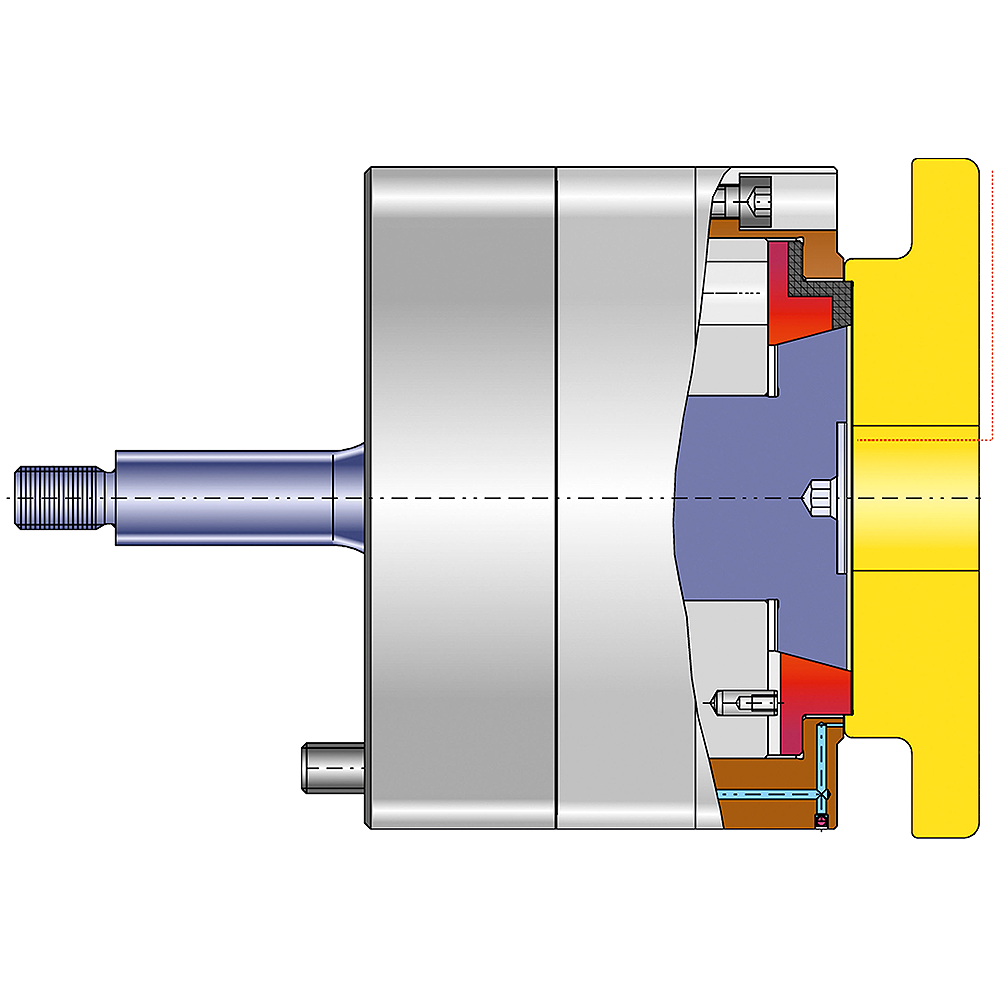

- Overall process time reduced by approx. 15 %

- Waiting time between the processes reduced to »0«

Results / customer benefits

- Adjustable eccentric mandrel with maximum eccentric dimension of 1 mm

- Complete machining of the workpiece with one machine

Challenge

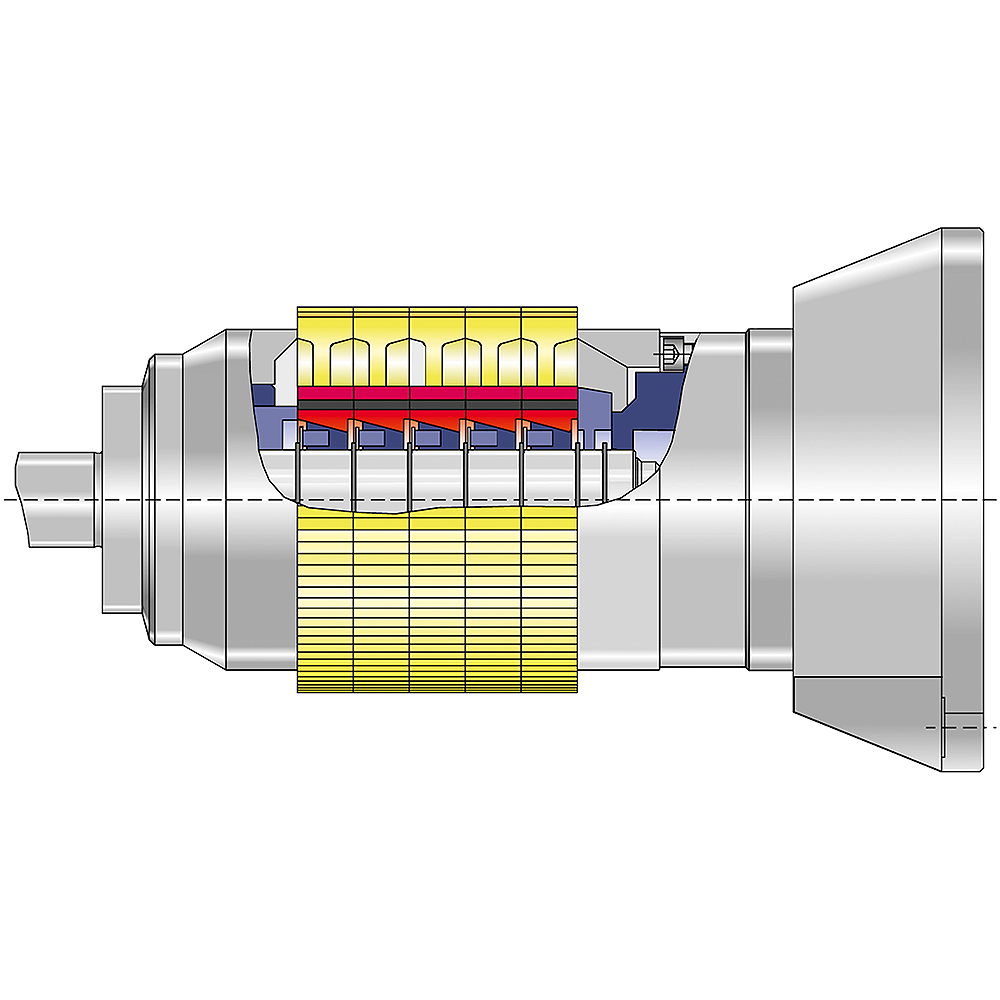

Workpiece: Eccentric sleeve

Clamping task: I.D. clamping

Machining: Turning

- Eccentric mandrel adjustment via the C-axis

- Centric and eccentric machining

- Clamping of different workpieces with one mandrel